Modern principles of maintenance management

Beskrivelse

Beskrivelse

Being responsible for operational safety or for maintenance functions places special competence requirements on those who hold these roles. Managing equipment and facilities to maintain technical level is not sufficient. Today, it is required that the production and maintenance organizations manage to develop their work sets, methods and the production plant itself in order to create efficient plants.

After completing the course, the participants will have increased knowledge to manage and develop operational safety and maintenance activities in accordance with today's more modern maintenance principles.

| Maintenance - terminology and standards | In order to have clear and secure communication, it is important that everyone who works with maintenance and operational safety, both in the production and maintenance organization, speaks the same language. This can be ensured by working with terminology and the definitions described in standard NS-EN13306:2017 |  |

|

Asset Management |

Asset Management is a combined and structured way of working for the management of facility assets during their entire life cycle. It includes a large number of processes, areas of expertise, tools and information that must work together at all stages. Examples of this are investment planning, risk management, operation and maintenance, but also management, culture and decision-making processes. Since 2014, there is a standard, ISO 55000, for Asset Management. |  |

| Maintenance costs |

In the section on maintenance costs, we review how maintenance affects the company's finances and the definitions of what maintenance costs are. We look at how these costs can be affected and how we can know what is a reasonable maintenance cost. |

|

|

LCC and LCP |

One important tool for securing/creating/making operationally reliable and total economic equipment (systems) is to integrate/adapt/incorporate the lifetime cost concept into the daily business. When it comes to purchasing, it is important to acquire the best financial alternatives, as it is of the utmost importance that all work with operational reliability aims to provide a low lifetime cost and a high lifetime profit. The concept is also incorporated into the construction- and sales work. |  |

|

From reactive to proactive maintenance |

Many companies have the ambition to move from reactive to proactive maintenance. We look at what is required and what activities are needed. |

|

| Planning and preparation | Good planning and good cooperation between production and maintenance are essential to create high efficiency in maintenance. Furthermore, those who are skilled at planning, will get an even utilization of resources and a good balance between internal and hired personnel. Preparation must be in place to make the work run smoothly and efficiently. The aim of preparation is to ensure that the right resources, materials and information are in place when the work starts. |  |

| Maintenance development |

In order to develop maintenance, it is required that a number of development activities take place within the maintenance business. We present a model for developing maintenance in a sequence that increases the chances of success. Furthermore, we describe the content and significance of these "building blocks" that constitutes Idhammar's maintenance pyramid.

|

|

| Key performance indicator, KPI | KPI can be a powerful support in maintenance development. We review the Maintenance KPI's in standard NS-EN15341:2019 + A1:2022 and discuss which indicators have the best impact in the development of operational reliability and maintenance. |  |

|

Informatjons systems for maintenance |

We look at "Best Practice", working with this within maintenance requires developing maintenance processes. All development of maintenance and operational safety is knowledge-driven. How do we gain knowledge about the condition of the equipment and the results of the activities we carry out? In the section on information systems for maintenance, we review the opportunities and challenges that a modern maintenance system provides. |  |

|

Maintenance development |

We look at how, in practice, we start a journey of development to evolve maintenance. We go through developing a strategy and a policy for maintenance and how the maintenance task should be formulated. We provide examples of successful and less successful maintenance development programs. We look at what costs are connected to a journey of development and what benefits it can bring. |  |

| IOT and digitalization | What is IOT and digitization? How to use IOT, Artificial intelligence AI, VR and Argumented reality in a maintenance context. |  |

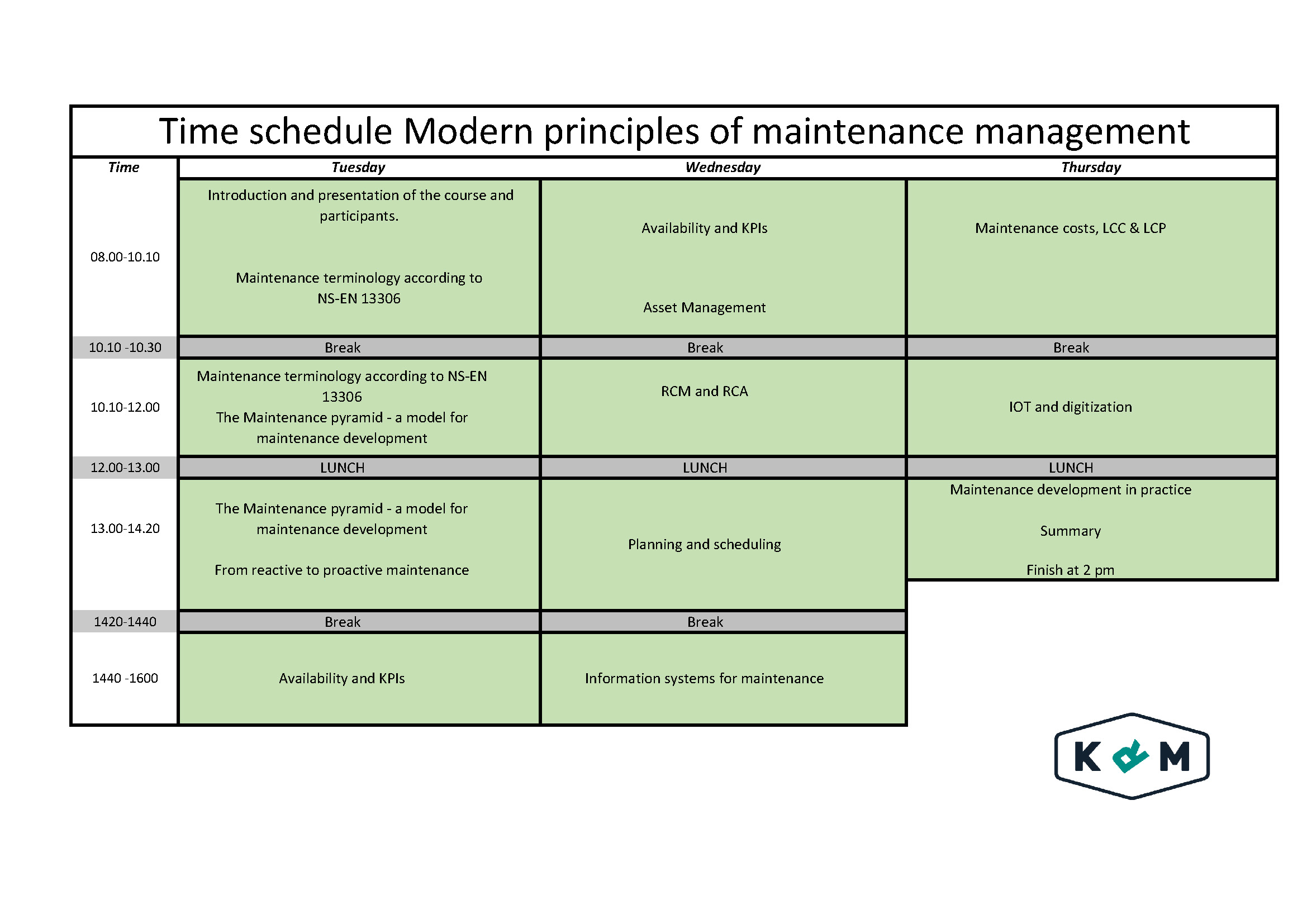

Time schedule

Time schedule

Other details

Other details

Target group:

Everyone involved in maintenance processes, maintenance managers and leaders, purchasers, operation- and maintenance personnel

Prerequisites:

No prior knowledge is required

Instructor:

- Annie Björk

Course certificate:

A course certificate is issued after completion of the course

Varighet

3 dager

Kursavgift

Kr 17400,-